Abstract

Nowadays, there are growing demands for developing economical and multi-functional polymeric materials that simultaneously have high thermal conductivity, optimized electrical conductivity, and improved mechanical properties. Due to its outstanding physical and mechanical properties, graphene can significantly endow epoxy polymers with novel properties. As obtaining large-scale production of graphene is crucial for developing epoxy composites, this review firstly provides insight into the newly developed methods that can balance between quality and scalability of graphene. Then, the thermal and electrical conduction mechanisms of graphene and its polymer composites are illustrated in detail. Additionally, the recent progress of graphene to concurrently regulate the thermal, electrical, and mechanical properties of epoxies is comprehensively reviewed, highlighting the influence of graphene aspect ratio, graphene derivatives, surface modification, orientation, dispersion, and the inclusion of hybrids. This study presents the state-of-the-art review of the established graphene-based epoxy composites for electrically conductive and insulative applications to provide comprehensive guidelines for researchers seeking to attain high-performance materials.

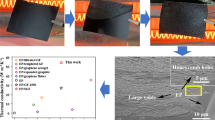

Graphical abstract

This article comprehensively and simultaneously reviews the recent advancements in thermal, electrical, and mechanical properties of graphene-based epoxy composites.

Copyright 2014, American Chemical Society. (c) Schematic of the cathodic electrochemical exfoliation mechanism. Reproduced with permission [133]. Copyright 2012, American Chemical Society. (d) Schematic of the high shear mixer and the dominating mechanisms, including the effect of shearing, jet cavitation, and collision between graphene sheets. Reproduced with permission [144]. Copyright 2014, RSC Publishing. (e) Schematic explanation of the fabrication of edge-selectively modified GnPs in a dry ball milling through the reaction between the active carbon species at the broken edges of GnPs and the reactant gases. The red ball refers to the reactant gases such as carbon dioxide, hydrogen, sulfur trioxide, and air moisture; (e') an example of the SEM micrograph of the exfoliated GnPs with carboxylic acid at their edges using carbon dioxide as the reactant gas. Reproduced with permission [107]. Copyright 2013, American Chemical Society

Copyright 2010, Wiley–VCH. (b) Schematic of the transition of polymer from insulative into conductive materials by the incorporation of different graphene loading showing the percolation and tunneling mechanisms

Copyright 2013, Elsevier. (c, d) Storage modulus versus temperature of epoxy and its composites reinforced with different dispersion states of RGO. Reproduced with permission [229]. Copyright 2013, Elsevier

Copyright 2014, Elsevier

Copyright 2011, Elsevier. (c, d) Electrical conductivity and relative Young’s modulus of different graphene-based epoxy composites as a function of the filler content. Reproduced with permission [292]. Copyright 2014, Wiley–VCH

Copyright 2015, Elsevier

Copyright 2018, Wiley–VCH

Copyright 2019, Elsevier. (d) AFM image of RGO revealing an average size of 400 ~ 600 nm with a thickness of ~ 0.8 nm. (e) Surface morphology of the fabricated 3DGF defining its unique porous structure; 3DGF was fabricated by CVD method with the presence of nickel foam rod. Reproduced under terms of the CC-BY license [311]. Copyright 2017, Springer Nature

Copyright 2020, Elsevier

Copyright 2019, IOP Publishing. (d) Schematic of the synthesis process of the pea-pod-like alumina-graphene epoxy composite. (e) In-plane and through-plane TC of the obtained composites. Reproduced with permission [96]. Copyright 2020, Elsevier

Copyright 2013, RSC Publishing

Copyright 2016, Elsevier

Copyright 2014, RSC Publishing

modified by 3-aminepropyltriethoxysilane coupling agent (APS or APTES) to produce h-BN-NH2. The self-assembly was achieved simply by mixing GO with h-BN in an appropriate ratio under continuous stirring for 2 h; then, the mixture was collected and vacuum dried. Reproduced with permission [355]. Copyright 2016, Elsevier

Copyright 2015, RSC Publishing

Copyright 2019, Elsevier

Copyright 2018, Wiley–VCH

Similar content being viewed by others

References

Khan J, Momin SA, Mariatti M (2020) A review on advanced carbon-based thermal interface materials for electronic devices. Carbon 168:65–112. https://doi.org/10.1016/j.carbon.2020.06.012

Shtein M, Nadiv R, Buzaglo M, Regev O (2015) Graphene-based hybrid composites for efficient thermal management of electronic devices. ACS Appl Mater Interfaces 7:23725–23730. https://doi.org/10.1021/acsami.5b07866

Singh AK, Panda BP, Mohanty S et al (2017) Synergistic effect of hybrid graphene and boron nitride on the cure kinetics and thermal conductivity of epoxy adhesives. Polym Adv Technol 28:1851–1864. https://doi.org/10.1002/pat.4072

Siwal SS, Zhang Q, Devi N, Thakur VK (2020) Carbon-based polymer nanocomposite for high-performance energy storage applications. Polymers 12. https://doi.org/10.3390/polym12030505

Zhang X, Samorì P (2017) Graphene/polymer nanocomposites for supercapacitors. ChemNanoMat 3:362–372. https://doi.org/10.1002/cnma.201700055

Lu X, Liu H, Murugadoss V et al (2020) Polyethylene glycol/carbon black shape-stable phase change composites for peak load regulating of electric power system and corresponding thermal energy storage. Engineered Science 9:25–34. https://doi.org/10.30919/es8d901

Zhou Y, Wu S, Ma Y et al (2020) Recent advances in organic/composite phase change materials for energy storage. ES Energy Environ 9:28–40. https://doi.org/10.30919/esee8c150

Zhao Y, Niu M, Yang F et al (2019) Ultrafast electro-thermal responsive heating film fabricated from graphene modified conductive materials. Engineered Science 8:33–38. https://doi.org/10.30919/es8d501

Yan X, Liu J, Khan MA et al (2020) Efficient solvent-free microwave irradiation synthesis of highly conductive polypropylene nanocomposites with lowly loaded carbon nanotubes. ES Mater Manuf 9:21–33. https://doi.org/10.30919/esmm5f716

Zhang D, Sun J, Lee LJ, Castro JM (2020) Overview of ultrasonic assisted manufacturing multifunctional carbon nanotube nanopaper based polymer nanocomposites. Engineered Science 10:35–50. https://doi.org/10.30919/es5e1002

Zhao B, Liang L, Bai Z et al (2021) Poly(vinylidene fluoride)/Cu@Ni anchored reduced-graphene oxide composite films with folding movement to boost microwave absorption properties. ES Energy Environ 14:79–86. https://doi.org/10.30919/esee8c488

Qi G, Liu Y, Chen L et al (2021) Lightweight Fe3C@Fe/C nanocomposites derived from wasted cornstalks with high-efficiency microwave absorption and ultrathin thickness. Adv Compos Hybrid Mater 4:1226–1238. https://doi.org/10.1007/s42114-021-00368-0

Yu Z, Bai Y, Wang JH, Li Y (2021) Effects of functional additives on structure and properties of polycarbonate-based composites filled with hybrid chopped carbon fiber/graphene nanoplatelet fillers. ES Energy Environ 12:66–76. https://doi.org/10.30919/esee8c434

Sun L, Liang L, Shi Z et al (2020) Optimizing strategy for the dielectric performance of topological-structured polymer nanocomposites by rationally tailoring the spatial distribution of nanofillers. Engineered Science 12:95–105. https://doi.org/10.30919/es8d1148

Han S, Meng Q, Xing K et al (2020) Epoxy/graphene film for lifecycle self-sensing and multifunctional applications. Compos Sci Technol 198:108312. https://doi.org/10.1016/j.compscitech.2020.108312

Wu H, Zhong Y, Tang Y et al (2021) Precise regulation of weakly negative permittivity in CaCu3Ti4O12 metacomposites by synergistic effects of carbon nanotubes and grapheme. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-021-00378-y

Dagdag O, Hsissou R, El Harfi A et al (2020) Fabrication of polymer based epoxy resin as effective anti-corrosive coating for steel: computational modeling reinforced experimental studies. Surfaces and Interfaces 18:100454. https://doi.org/10.1016/j.surfin.2020.100454

Zhu Q, Huang Y, Li Y et al (2021) Aluminum dihydric tripolyphosphate/polypyrrole-functionalized graphene oxide waterborne epoxy composite coatings for impermeability and corrosion protection performance of metals. Adv Compos Hybrid Mater 4:780–792. https://doi.org/10.1007/s42114-021-00265-6

Madhusudhana AM, Mohana KNS, Hegde MB et al (2020) Functionalized graphene oxide-epoxy phenolic novolac nanocomposite: an efficient anticorrosion coating on mild steel in saline medium. Adv Compos Hybrid Mater 3:141–155. https://doi.org/10.1007/s42114-020-00142-8

Das R, Vupputuri S, Hu Q et al (2020) Synthesis and characterization of antiflammable vinyl ester resin nanocomposites with surface functionalized nanotitania. ES Mater Manuf 8:46–53. https://doi.org/10.30919/esmm5f709

Liang C, Du Y, Wang Y et al (2021) Intumescent fire-retardant coatings for ancient wooden architectures with ideal electromagnetic interference shielding. Adv Compos Hybrid Mater. https://doi.org/10.1007/s42114-021-00274-5

Yin Y, Jiang B, Zhu X et al (2019) Investigation of thermostability of modified graphene oxide/methylsilicone resin nanocomposites. Engineered Science 5:73–78. https://doi.org/10.30919/es8d762

Naskar AK, Keum JK, Boeman RG (2016) Polymer matrix nanocomposites for automotive structural components. Nat Nanotechnol 11:1026–1030. https://doi.org/10.1038/nnano.2016.262

Back J-H, Hwang J-U, Lee Y-H et al (2018) Morphological study and mechanical property of epoxy-foam adhesives based on epoxy composites for automotive applications. Int J Adhes Adhes 87:124–129. https://doi.org/10.1016/j.ijadhadh.2018.09.010

Kausar A, Rafique I, Muhammad B (2017) Aerospace application of polymer nanocomposite with carbon nanotube, graphite, graphene oxide, and nanoclay. Polym Plast Technol Eng 56:1438–1456. https://doi.org/10.1080/03602559.2016.1276594

Baur J, Silverman E (2007) Challenges and opportunities in multifunctional nanocomposite structures for aerospace applications. MRS Bull 32:328–334. https://doi.org/10.1557/mrs2007.231

Zhao S, Pei L, Li H et al (2021) Research progress in toughening modification of polybenzoxazine. Engineered Science 14:14–26. https://doi.org/10.30919/es8d1150

Zhang Y, Zhan L (2020) Preparation and damping properties of Al2O3 hollow spheres/epoxy composites encapsulating Q195 steel pipes. ES Mater Manuf 10:60–66. https://doi.org/10.30919/esmm5f925

Atta OM, Manan S, Ul-Islam MU et al (2021) Silver decorated bacterial cellulose nanocomposites as antimicrobial food packaging materials. ES Food Agrofor 6:12–26. https://doi.org/10.30919/esfaf590

Silva-Leyton R, Quijada R, Bastías R et al (2019) Polyethylene/graphene oxide composites toward multifunctional active packaging films. Compos Sci Technol 184:107888. https://doi.org/10.1016/j.compscitech.2019.107888

Al-Harbi N Al, Hussein MA, Al-Hadeethi Y Al, Umar A (2022) Cellulose acetate-hydroxyapatite-bioglass-zirconia nanocomposite particles as potential biomaterial: synthesis, characterization, and biological properties for bone application. Engineered Science 17:70–82. https://doi.org/10.30919/es8d528

Vyas S, Shukla A, Shivhare SJ et al (2022) High performance conducting nanocomposites polyaniline (PANI)-CuO with enhanced antimicrobial activity for biomedical applications. ES Mater Manuf 15:46–52. https://doi.org/10.30919/esmm5f468

He Z, Yan Y, Zhang Z (2021) Thermal management and temperature uniformity enhancement of electronic devices by micro heat sinks: a review. Energy 216:119223. https://doi.org/10.1016/j.energy.2020.119223

Moore AL, Shi L (2014) Emerging challenges and materials for thermal management of electronics. Mater Today 17:163–174. https://doi.org/10.1016/j.mattod.2014.04.003

Raimondo M, Guadagno L, Speranza V et al (2018) Multifunctional graphene/POSS epoxy resin tailored for aircraft lightning strike protection. Compos Part B Eng 140:44–56. https://doi.org/10.1016/j.compositesb.2017.12.015

Gu H, Zhang H, Ma C et al (2019) Trace electrosprayed nanopolystyrene facilitated dispersion of multiwalled carbon nanotubes: simultaneously strengthening and toughening epoxy. Carbon 142:131–140. https://doi.org/10.1016/j.carbon.2018.10.029

Gu J, Dang J, Wu Y et al (2012) Flame-retardant, thermal, mechanical and dielectric properties of structural non-halogenated epoxy resin composites. Polym Plast Technol Eng 51:1198–1203. https://doi.org/10.1080/03602559.2012.694951

Ahmed A, Sanada K (2019) Micromechanical modeling and experimental verification of self-healing microcapsules-based composites. Mech Mater 131:84–92. https://doi.org/10.1016/j.mechmat.2019.01.020

Yuan W, Xiao Q, Li L, Xu T (2016) Thermal conductivity of epoxy adhesive enhanced by hybrid graphene oxide/AlN particles. Appl Therm Eng 106:1067–1074. https://doi.org/10.1016/j.applthermaleng.2016.06.089

Gu J, Zhang Q, Li H et al (2007) Study on preparation of SiO2/epoxy resin hybrid materials by means of sol-gel. Polym Plast Technol Eng 46:1129–1134. https://doi.org/10.1080/03602550701558033

Gu J, Zhang Q, Dang J et al (2009) Preparation and mechanical properties researches of silane coupling reagent modified β-silicon carbide filled epoxy composites. Polym Bull 62:689–697. https://doi.org/10.1007/s00289-009-0045-z

Shi K, Shen Y, Zhang Y, Wang T (2019) A modified imidazole as a novel latent curing agent with toughening effect for epoxy. Engineered Science 5:66–72. https://doi.org/10.30919/es8d639

Rimdusit S, Ishida H (2000) Development of new class of electronic packaging materials based on ternary systems of benzoxazine, epoxy, and phenolic resins. Polymer 41:7941–7949. https://doi.org/10.1016/S0032-3861(00)00164-6

Jing X, Wei J, Liu Y et al (2020) Deployment analysis of aramid fiber reinforced shape-memory epoxy resin composites. Engineered Science 11:44–53. https://doi.org/10.30919/es8d1120

Akhtar MW, Kim JS, Memon MA, Baloch MM (2020) Hybridization of hexagonal boron nitride nanosheets and multilayer graphene: enhanced thermal properties of epoxy composites. Compos Sci Technol 195:108183. https://doi.org/10.1016/j.compscitech.2020.108183

Ruan K, Zhong X, Shi X et al (2021) Liquid crystal epoxy resins with high intrinsic thermal conductivities and their composites: a mini-review. Mater Today Phys 20:100456. https://doi.org/10.1016/j.mtphys.2021.100456

Yang X, Zhong X, Zhang J, Gu J (2021) Intrinsic high thermal conductive liquid crystal epoxy film simultaneously combining with excellent intrinsic self-healing performance. J Mater Sci Technol 68:209–215. https://doi.org/10.1016/j.jmst.2020.08.027

Xu Y, Chung DDL, Mroz C (2001) Thermally conducting aluminum nitride polymer-matrix composites. Compos - Part A Appl Sci Manuf 32:1749–1757. https://doi.org/10.1016/S1359-835X(01)00023-9

Wang Z, Iizuka T, Kozako M et al (2011) Development of epoxy/BN composites with high thermal conductivity and sufficient dielectric breakdown strength partI - sample preparations and thermal conductivity. IEEE Trans Dielectr Electr Insul 18:1963–1972. https://doi.org/10.1109/TDEI.2011.6118634

Yao XF, Zhou D, Yeh HY (2008) Macro/microscopic fracture characterizations of SiO2/epoxy nanocomposites. Aerosp Sci Technol 12:223–230. https://doi.org/10.1016/j.ast.2007.03.005

McGrath LM, Parnas RS, King SH et al (2008) Investigation of the thermal, mechanical, and fracture properties of alumina-epoxy composites. Polymer 49:999–1014. https://doi.org/10.1016/j.polymer.2007.12.014

Mamunya YP, Davydenko V V, Pissis P, Lebedev E V (2002) Electrical and thermal conductivity of polymers filled with metal powders. Eur Polym J 38:1887–1897. https://doi.org/10.1016/S0014-3057(02)00064-2

Corcione CE, Maffezzoli A (2013) Transport properties of graphite/epoxy composites: thermal, permeability and dielectric characterization. Polym Test 32:880–888. https://doi.org/10.1016/j.polymertesting.2013.03.023

Chen YM, Ting JM (2002) Ultra high thermal conductivity polymer composites. Carbon 40:359–362. https://doi.org/10.1016/S0008-6223(01)00112-9

Fan W, Li JL, Zheng YY et al (2016) Influence of thermo-oxidative aging on the thermal conductivity of carbon fiber fabric reinforced epoxy composites. Polym Degrad Stab 123:162–169. https://doi.org/10.1016/j.polymdegradstab.2015.11.016

Zhou W (2011) Effect of coupling agents on the thermal conductivity of aluminum particle/epoxy resin composites. J Mater Sci 46:3883–3889. https://doi.org/10.1007/s10853-011-5309-y

Fu Y, He Z, Mo D, Lu S (2014) Thermal conductivity enhancement with different fillers for epoxy resin adhesives. Appl Therm Eng 66:493–498. https://doi.org/10.1016/j.applthermaleng.2014.02.044

Permal A, Devarajan M, Hung HL et al (2018) Controlled high filler loading of functionalized Al2O3-filled epoxy composites for LED thermal management. J Mater Eng Perform 27:1296–1307. https://doi.org/10.1007/s11665-018-3151-y

Novoselov KS, Geim AK, Morozov SV et al (2004) Electric field effect in atomically thin carbon films. Science 306:666–669. https://doi.org/10.1126/science.39.1002.398

Lemine AS, Zagho MM, Altahtamouni TM, Bensalah N (2018) Graphene a promising electrode material for supercapacitors—a review. Int J Energy Res 42:4284–4300. https://doi.org/10.1002/er.4170

Suriani AB, Muqoyyanah MA et al (2020) Synthesis, transfer and application of graphene as a transparent conductive film: a review. Bull Mater Sci 43:310. https://doi.org/10.1007/s12034-020-02270-9

Hosseinzadeh A, Bidmeshkipour S, Abdi Y et al (2018) Graphene based strain sensors: a comparative study on graphene and its derivatives. Appl Surf Sci 448:71–77. https://doi.org/10.1016/j.apsusc.2018.04.099

Mehmood A, Mubarak NM, Khalid M et al (2020) Graphene based nanomaterials for strain sensor application—a review. J Environ Chem Eng 8:103743. https://doi.org/10.1016/j.jece.2020.103743

Gijare M, Chaudhari S, Ekar S, Garje A (2021) Reduced graphene oxide based electrochemical nonenzymatic human serum glucose sensor. ES Mater Manuf 14:110–119. https://doi.org/10.30919/esmm5f486

Hossain S, Abdalla AM, Suhaili SBH et al (2020) Nanostructured graphene materials utilization in fuel cells and batteries: a review. J Energy Storage 29:101386. https://doi.org/10.1016/j.est.2020.101386

Lee SH, Kakati N, Jee SH et al (2011) Hydrothermal synthesis of PtRu nanoparticles supported on graphene sheets for methanol oxidation in direct methanol fuel cell. Mater Lett 65:3281–3284. https://doi.org/10.1016/j.matlet.2011.07.025

Kaskhedikar NA, Maier J (2009) Lithium storage in carbon nanostructures. Adv Mater 21:2664–2680. https://doi.org/10.1002/adma.200901079

Potts JR, Dreyer DR, Bielawski CW, Ruoff RS (2011) Graphene-based polymer nanocomposites. Polymer 52:5–25. https://doi.org/10.1016/j.polymer.2010.11.042

Li A, Zhang C, Zhang Y-F (2017) Thermal conductivity of graphene-polymer composites: mechanisms, properties, and applications. Polymers 9. https://doi.org/10.3390/polym9090437

Sun Z, Huang X, Xia A et al (2021) Tunable bandwidth of negative permittivity from graphene-silicon carbide ceramics. Engineered Science 16:19–25. https://doi.org/10.30919/es8d564

Allen MJ, Tung VC, Kaner RB (2010) Honeycomb carbon: a review of graphene. Chem Rev 110:132–145

Balandin AA, Ghosh S, Bao W et al (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8:902–907. https://doi.org/10.1021/nl0731872

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6:183–191

Lee C, Wei X, Kysar JW, Hone J (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321:385–388. https://doi.org/10.1126/science.1157996

Nair RR, Blake P, Grigorenko AN et al (2008) Fine structure constant defines visual transparency of graphene. Science 320:1308. https://doi.org/10.1126/science.1156965

Stankovich S, Dikin DA, Dommett GHB et al (2006) Graphene-based composite materials. Nature 442:282–286. https://doi.org/10.1038/nature04969

Jiao L, Zhang L, Wang X et al (2009) Narrow graphene nanoribbons from carbon nanotubes. Nature 458:877–880. https://doi.org/10.1038/nature07919

Kim KS, Zhao Y, Jang H et al (2009) Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 457:706–710. https://doi.org/10.1038/nature07719

de Heer WA, Berger C, Wu X et al (2007) Epitaxial graphene. Solid State Commun 143:92–100. https://doi.org/10.1016/j.ssc.2007.04.023

Hass J, de Heer WA, Conrad EH (2008) The growth and morphology of epitaxial multilayer graphene. J Phys Condens Matter 20:323202. https://doi.org/10.1088/0953-8984/20/32/323202

Shi G, Araby S, Gibson CT et al (2018) Graphene platelets and their polymer composites: fabrication, structure, properties, and applications. Adv Funct Mater 28:1706705. https://doi.org/10.1002/adfm.201706705

Kim SY, Noh YJ, Yu J (2015) Thermal conductivity of graphene nanoplatelets filled composites fabricated by solvent-free processing for the excellent filler dispersion and a theoretical approach for the composites containing the geometrized fillers. Compos Part A Appl Sci Manuf 69:219–225. https://doi.org/10.1016/j.compositesa.2014.11.018

Singh V, Joung D, Zhai L et al (2011) Graphene based materials: past, present and future. Prog Mater Sci 56:1178–1271. https://doi.org/10.1016/j.pmatsci.2011.03.003

Chandrasekaran S, Seidel C, Schulte K (2013) Preparation and characterization of graphite nano-platelet (GNP)/epoxy nano-composite: mechanical, electrical and thermal properties. Eur Polym J 49:3878–3888. https://doi.org/10.1016/j.eurpolymj.2013.10.008

Bustero I, Gaztelumendi I, Obieta I et al (2020) Free-standing graphene films embedded in epoxy resin with enhanced thermal properties. Adv Compos Hybrid Mater 3:31–40. https://doi.org/10.1007/s42114-020-00136-6

Li J, Zhang P, He H et al (2019) Enhanced thermal transport properties of epoxy resin thermal interface materials. ES Energy Environ 4:41–47

Noh YJ, Joh H-I, Yu J et al (2015) Ultra-high dispersion of graphene in polymer composite via solvent freefabrication and functionalization. Sci Rep 5:9141. https://doi.org/10.1038/srep09141

Kim HS, Bae HS, Yu J, Kim SY (2016) Thermal conductivity of polymer composites with the geometrical characteristics of graphene nanoplatelets. Sci Rep 6:26825. https://doi.org/10.1038/srep26825

Kashfipour MA, Mehra N, Zhu J (2018) A review on the role of interface in mechanical, thermal, and electrical properties of polymer composites. Adv Compos Hybrid Mater 1:415–439. https://doi.org/10.1007/s42114-018-0022-9

Park J, Yan M (2013) Covalent functionalization of graphene with reactive intermediates. Acc Chem Res 46:181–189. https://doi.org/10.1021/ar300172h

Chiang TH, Liu C, Lin Y (2015) The effect of an anhydride curing agent, an accelerant, and non-ionic surfactants on the electrical resistivity of graphene/epoxy composites. J Appl Polym Sci 132. https://doi.org/10.1002/app.41975

Kazemi-Khasragh E, Bahari-Sambran F, Siadati SMH et al (2019) The effects of surface-modified graphene nanoplatelets on the sliding wear properties of basalt fibers-reinforced epoxy composites. J Appl Polym Sci 136:47986. https://doi.org/10.1002/app.47986

Stankovich S, Dikin DA, Piner RD et al (2007) Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45:1558–1565. https://doi.org/10.1016/j.carbon.2007.02.034

Dikin DA, Stankovich S, Zimney EJ et al (2007) Preparation and characterization of graphene oxide paper. Nature 448:457–460. https://doi.org/10.1038/nature06016

Gómez-Navarro C, Weitz RT, Bittner AM et al (2007) Electronic transport properties of individual chemically reduced graphene oxide sheets. Nano Lett 7:3499–3503. https://doi.org/10.1021/nl072090c

Chen Y, Hou X, Liao M et al (2020) Constructing a “pea-pod-like” alumina-graphene binary architecture for enhancing thermal conductivity of epoxy composite. Chem Eng J 381:122690. https://doi.org/10.1016/j.cej.2019.122690

Yu J, Choi HK, Kim HS, Kim SY (2016) Synergistic effect of hybrid graphene nanoplatelet and multi-walled carbon nanotube fillers on the thermal conductivity of polymer composites and theoretical modeling of the synergistic effect. Compos Part A Appl Sci Manuf 88:79–85. https://doi.org/10.1016/j.compositesa.2016.05.022

Noh YJ, Kim SY (2015) Synergistic improvement of thermal conductivity in polymer composites filled with pitch based carbon fiber and graphene nanoplatelets. Polym Test 45:132–138. https://doi.org/10.1016/j.polymertesting.2015.06.003

Kazemi-Khasragh E, Bahari-Sambran F, Platzer C, Eslami-Farsani R (2020) The synergistic effect of graphene nanoplatelets–montmorillonite hybrid system on tribological behavior of epoxy-based nanocomposites. Tribol Int 151:106472. https://doi.org/10.1016/j.triboint.2020.106472

Ghosh S, Bao W, Nika DL et al (2010) Dimensional crossover of thermal transport in few-layer graphene. Nat Mater 9:555

Chen J, Yao B, Li C, Shi G (2013) An improved Hummers method for eco-friendly synthesis of graphene oxide. Carbon 64:225–229. https://doi.org/10.1016/j.carbon.2013.07.055

Oliveira AEF, Braga GB, Tarley CRT, Pereira AC (2018) Thermally reduced graphene oxide: synthesis, studies and characterization. J Mater Sci 53:12005–12015. https://doi.org/10.1007/s10853-018-2473-3

Nidamanuri N, Li Y, Li Q, Dong M (2020) Graphene and graphene oxide-based membranes for gas separation. Engineered Science 9:3–16. https://doi.org/10.30919/es8d128906

Abdelkader AM, Cooper AJ, Dryfe RAW, Kinloch IA (2015) How to get between the sheets: a review of recent works on the electrochemical exfoliation of graphene materials from bulk graphite. Nanoscale 7:6944–6956. https://doi.org/10.1039/C4NR06942K

Zaman I, Kuan H-C, Dai J et al (2012) From carbon nanotubes and silicate layers to graphene platelets for polymer nanocomposites. Nanoscale 4:4578–4586. https://doi.org/10.1039/C2NR30837A

Paton KR, Varrla E, Backes C et al (2014) Scalable production of large quantities of defect-free few-layer graphene by shear exfoliation in liquids. Nat Mater 13:624–630. https://doi.org/10.1038/nmat3944

Jeon I-Y, Choi H-J, Jung S-M et al (2013) Large-scale production of edge-selectively functionalized graphene nanoplatelets via ball milling and their use as metal-free electrocatalysts for oxygen reduction reaction. J Am Chem Soc 135:1386–1393. https://doi.org/10.1021/ja3091643

Brodie BC (1859) XIII. On the atomic weight of graphite. Phil Trans R Soc 149:249–259. https://doi.org/10.1098/rstl.1859.0013

Staudenmaier L (1898) Verfahren zur Darstellung der Graphitsäure. Berichte der Dtsch Chem Gesellschaft 31:1481–1487. https://doi.org/10.1002/cber.18980310237

Hummers WS, Offeman RE (1958) Preparation of graphitic oxide. J Am Chem Soc 80:1339. https://doi.org/10.1021/ja01539a017

Marcano DC, Kosynkin DV, Berlin JM et al (2010) Improved synthesis of graphene oxide. ACS Nano 4:4806–4814. https://doi.org/10.1021/nn1006368

Liu H, Mao Y (2021) Graphene oxide-based nanomaterials for uranium adsorptive uptake. ES Mater Manuf 13:3–22. https://doi.org/10.30919/esmm5f453

Moon IK, Lee J, Ruoff RS, Lee H (2010) Reduced graphene oxide by chemical graphitization. Nat Commun 1:73. https://doi.org/10.1038/ncomms1067

Li D, Müller MB, Gilje S et al (2008) Processable aqueous dispersions of graphene nanosheets. Nat Nanotechnol 3:101–105. https://doi.org/10.1038/nnano.2007.451

Park S, An J, Potts JR et al (2011) Hydrazine-reduction of graphite- and graphene oxide. Carbon 49:3019–3023. https://doi.org/10.1016/j.carbon.2011.02.071

Shin H-J, Kim KK, Benayad A et al (2009) Efficient reduction of graphite oxide by sodium borohydride and its effect on electrical conductance. Adv Funct Mater 19:1987–1992. https://doi.org/10.1002/adfm.200900167

Si Y, Samulski ET (2008) Synthesis of water soluble graphene. Nano Lett 8:1679–1682. https://doi.org/10.1021/nl080604h

Wang G, Yang J, Park J et al (2008) Facile synthesis and characterization of graphene nanosheets. J Phys Chem C 112:8192–8195. https://doi.org/10.1021/jp710931h

Pei S, Zhao J, Du J et al (2010) Direct reduction of graphene oxide films into highly conductive and flexible graphene films by hydrohalic acids. Carbon 48:4466–4474. https://doi.org/10.1016/j.carbon.2010.08.006

Dua V, Surwade SP, Ammu S et al (2010) All-organic vapor sensor using inkjet-printed reduced graphene oxide. Angew Chemie Int Ed 49:2154–2157. https://doi.org/10.1002/anie.200905089

Pei S, Cheng H-M (2012) The reduction of graphene oxide. Carbon 50:3210–3228. https://doi.org/10.1016/j.carbon.2011.11.010

Aghamohammadi H, Eslami-Farsani R, Torabian M, Amousa N (2020) Recent advances in one-pot functionalization of graphene using electrochemical exfoliation of graphite: a review study. Synth Met 269:116549. https://doi.org/10.1016/j.synthmet.2020.116549

Ejigu A, Miller B, Kinloch IA, Dryfe RAW (2018) Optimisation of electrolytic solvents for simultaneous electrochemical exfoliation and functionalisation of graphene with metal nanostructures. Carbon 128:257–266. https://doi.org/10.1016/j.carbon.2017.11.081

Liu J, Yang H, Zhen SG et al (2013) A green approach to the synthesis of high-quality graphene oxide flakes via electrochemical exfoliation of pencil core. RSC Adv 3:11745–11750. https://doi.org/10.1039/C3RA41366G

Aghamohammadi H, Eslami-Farsani R (2020) An experimental investigation on the sulfur and nitrogen co-doping and oxidation of prepared graphene by electrochemical exfoliation of pencil graphite rods. Ceram Int 46:28860–28869. https://doi.org/10.1016/j.ceramint.2020.08.052

Parvez K, Wu Z-S, Li R et al (2014) Exfoliation of graphite into graphene in aqueous solutions of inorganic salts. J Am Chem Soc 136:6083–6091. https://doi.org/10.1021/ja5017156

Zhang W, Zeng Y, Xiao N et al (2012) One-step electrochemical preparation of graphene-based heterostructures for Li storage. J Mater Chem 22:8455–8461. https://doi.org/10.1039/C2JM16315B

Su C-Y, Lu A-Y, Xu Y et al (2011) High-quality thin graphene films from fast electrochemical exfoliation. ACS Nano 5:2332–2339. https://doi.org/10.1021/nn200025p

Shih C-J, Lin S, Strano MS, Blankschtein D (2010) Understanding the stabilization of liquid-phase-exfoliated graphene in polar solvents: molecular dynamics simulations and kinetic theory of colloid aggregation. J Am Chem Soc 132:14638–14648. https://doi.org/10.1021/ja1064284

Yu P, Lowe SE, Simon GP, Zhong YL (2015) Electrochemical exfoliation of graphite and production of functional graphene. Curr Opin Colloid Interface Sci 20:329–338. https://doi.org/10.1016/j.cocis.2015.10.007

Parviz D, Irin F, Shah SA et al (2016) Challenges in liquid-phase exfoliation, processing, and assembly of pristine graphene. Adv Mater 28:8796–8818. https://doi.org/10.1002/adma.201601889

Wang J, Manga KK, Bao Q, Loh KP (2011) High-yield synthesis of few-layer graphene flakes through electrochemical expansion of graphite in propylene carbonate electrolyte. J Am Chem Soc 133:8888–8891. https://doi.org/10.1021/ja203725d

Zhong YL, Swager TM (2012) Enhanced electrochemical expansion of graphite for in situ electrochemical functionalization. J Am Chem Soc 134:17896–17899. https://doi.org/10.1021/ja309023f

Yang S, Ricciardulli AG, Liu S et al (2017) Ultrafast delamination of graphite into high-quality graphene using alternating currents. Angew Chemie Int Ed 56:6669–6675. https://doi.org/10.1002/anie.201702076

Achee TC, Sun W, Hope JT et al (2018) High-yield scalable graphene nanosheet production from compressed graphite using electrochemical exfoliation. Sci Rep 8:14525. https://doi.org/10.1038/s41598-018-32741-3

Shinde DB, Brenker J, Easton CD et al (2016) Shear assisted electrochemical exfoliation of graphite to graphene. Langmuir 32:3552–3559. https://doi.org/10.1021/acs.langmuir.5b04209

Chen G, Weng W, Wu D et al (2004) Preparation and characterization of graphite nanosheets from ultrasonic powdering technique. Carbon 42:753–759. https://doi.org/10.1016/j.carbon.2003.12.074

Kovtyukhova NI, Wang Y, Berkdemir A et al (2014) Non-oxidative intercalation and exfoliation of graphite by Brønsted acids. Nat Chem 6:957–963. https://doi.org/10.1038/nchem.2054

Yoshida A, Hishiyama Y, Inagaki M (1991) Exfoliated graphite from various intercalation compounds. Carbon 29:1227–1231. https://doi.org/10.1016/0008-6223(91)90040-P

Yasmin A, Luo JJ, Daniel IM (2006) Processing of expanded graphite reinforced polymer nanocomposites. Compos Sci Technol 66:1182–1189. https://doi.org/10.1016/j.compscitech.2005.10.014

Yu A, Ramesh P, Itkis ME et al (2007) Graphite nanoplatelet - epoxy composite thermal interface materials. J Phys Chem C 111:7565–7569. https://doi.org/10.1021/jp071761s

Bracamonte MV, Lacconi GI, Urreta SE, Foa Torres LEF (2014) On the nature of defects in liquid-phase exfoliated graphene. J Phys Chem C 118:15455–15459. https://doi.org/10.1021/jp501930a

Yi M, Shen Z, Liang S et al (2013) Water can stably disperse liquid-exfoliated graphene. Chem Commun 49:11059–11061. https://doi.org/10.1039/C3CC46457A

Liu L, Shen Z, Yi M et al (2014) A green, rapid and size-controlled production of high-quality graphene sheets by hydrodynamic forces. RSC Adv 4:36464–36470. https://doi.org/10.1039/C4RA05635C

Varrla E, Paton KR, Backes C et al (2014) Turbulence-assisted shear exfoliation of graphene using household detergent and a kitchen blender. Nanoscale 6:11810–11819. https://doi.org/10.1039/C4NR03560G

Yi M, Shen Z (2014) Kitchen blender for producing high-quality few-layer graphene. Carbon 78:622–626. https://doi.org/10.1016/j.carbon.2014.07.035

Rouzafzay F, Shidpour R, Al-Abri MZM et al (2020) Graphene@ZnO nanocompound for short-time water treatment under sun-simulated irradiation: effect of shear exfoliation of graphene using kitchen blender on photocatalytic degradation. J Alloys Compd 829:154614. https://doi.org/10.1016/j.jallcom.2020.154614

Kairi MI, Dayou S, Kairi NI et al (2018) Toward high production of graphene flakes – a review on recent developments in their synthesis methods and scalability. J Mater Chem A 6:15010–15026. https://doi.org/10.1039/C8TA04255A

Yi M, Shen Z (2015) A review on mechanical exfoliation for the scalable production of graphene. J Mater Chem A 3:11700–11715. https://doi.org/10.1039/C5TA00252D

Lv Y, Yu L, Jiang C et al (2014) Synthesis of graphene nanosheet powder with layer number control via a soluble salt-assisted route. RSC Adv 4:13350–13354. https://doi.org/10.1039/C3RA45060K

Zhao S, Niu M, Peng P et al (2020) Edge oleylaminated graphene as ultra-stable lubricant additive for friction and wear reduction. Engineered Science 9:77–83. https://doi.org/10.30919/es8d807

Amiri A, Naraghi M, Ahmadi G et al (2018) A review on liquid-phase exfoliation for scalable production of pure graphene, wrinkled, crumpled and functionalized graphene and challenges. FlatChem 8:40–71. https://doi.org/10.1016/j.flatc.2018.03.004

Liu L, Xiong Z, Hu D et al (2013) Production of high quality single- or few-layered graphene by solid exfoliation of graphite in the presence of ammonia borane. Chem Commun 49:7890–7892. https://doi.org/10.1039/C3CC43670E

León V, Quintana M, Herrero MA et al (2011) Few-layer graphenes from ball-milling of graphite with melamine. Chem Commun 47:10936–10938. https://doi.org/10.1039/C1CC14595A

F Wang LT Drzal Y Qin Z Huang 2015 Mechanical properties and thermal conductivity of graphene nanoplatelet/epoxy composites J Mater Sci 50 1082 1093 https://doi.org/10.1007/s10853-014-8665-6

Teng C, Xie D, Wang J et al (2017) Ultrahigh conductive graphene paper based on ball-milling exfoliated graphene. Adv Funct Mater 27:1700240. https://doi.org/10.1002/adfm.201700240

Mahanta NK, Abramson AR (2012) Thermal conductivity of graphene and graphene oxide nanoplatelets. In: 13th InterSociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems. pp 1–6

Fang X-Y, Yu X-X, Zheng H-M et al (2015) Temperature- and thickness-dependent electrical conductivity of few-layer graphene and graphene nanosheets. Phys Lett A 379:2245–2251. https://doi.org/10.1016/j.physleta.2015.06.063

Lee C, Wei X, Li Q et al (2009) Elastic and frictional properties of graphene. Phys status solidi 246:2562–2567. https://doi.org/10.1002/pssb.200982329

Gómez-Navarro C, Burghard M, Kern K (2008) Elastic properties of chemically derived single graphene sheets. Nano Lett 8:2045–2049. https://doi.org/10.1021/nl801384y

Burger N, Laachachi A, Ferriol M et al (2016) Review of thermal conductivity in composites: mechanisms, parameters and theory. Prog Polym Sci 61:1–28. https://doi.org/10.1016/j.progpolymsci.2016.05.001

Kashfipour MA, Mehra N, Dent RS, Zhu J (2019) Regulating intermolecular chain interaction of biopolymer with natural polyol for flexible, optically transparent and thermally conductive hybrids. Engineered Science 8:11–18. https://doi.org/10.30919/es8d508

Guo Y, Ruan K, Shi X et al (2020) Factors affecting thermal conductivities of the polymers and polymer composites: a review. Compos Sci Technol 193:108134. https://doi.org/10.1016/j.compscitech.2020.108134

Osman A, Elhakeem A, Kaytbay S, Ahmed A (2020) Influence of different nano-structured fillers on the performance of epoxy nanocomposites. Nano Hybrids Compos 29:51–60. https://doi.org/10.4028/www.scientific.net/NHC.29.51

Vadivelu MA, Kumar CR, Joshi GM (2016) Polymer composites for thermal management: a review. Compos Interfaces 23:847–872. https://doi.org/10.1080/09276440.2016.1176853

Yu W, Xie H, Yin L et al (2015) Exceptionally high thermal conductivity of thermal grease: synergistic effects of graphene and alumina. Int J Therm Sci 91:76–82. https://doi.org/10.1016/j.ijthermalsci.2015.01.006

Han H, Sun H, Lei F et al (2022) Flexible ethylene-vinyl acetate copolymer/fluorographene composite films with excellent thermal conductive and electrical insulation properties for thermal management. ES Mater Manuf 15:53–64. https://doi.org/10.30919/esmm5f523

Lv X, Tang Y, Tian Q et al (2020) Ultra-stretchable membrane with high electrical and thermal conductivity via electrospinning and in-situ nanosilver deposition. Compos Sci Technol 200:108414. https://doi.org/10.1016/j.compscitech.2020.108414

Sun J, Zhang X, Du Q et al (2021) The contribution of conductive network conversion in thermal conductivity enhancement of polymer composite: a theoretical and experimental study. ES Mater Manuf 13:53–65. https://doi.org/10.30919/esmm5f450

Guo Y, Ruan K, Gu J (2021) Controllable thermal conductivity in composites by constructing thermal conduction networks. Mater Today Phys 20:100449. https://doi.org/10.1016/j.mtphys.2021.100449

Yang X, Liang C, Ma T et al (2018) A review on thermally conductive polymeric composites: classification, measurement, model and equations, mechanism and fabrication methods. Adv Compos Hybrid Mater 1:207–230. https://doi.org/10.1007/s42114-018-0031-8

Jasmee S, Omar G, Othaman SSC et al (2021) Interface thermal resistance and thermal conductivity of polymer composites at different types, shapes, and sizes of fillers: a review. Polym Compos 42:2629–2652. https://doi.org/10.1002/pc.26029

Shen X, Wang Z, Wu Y et al (2016) Multilayer graphene enables higher efficiency in improving thermal conductivities of graphene/epoxy composites. Nano Lett 16:3585–3593. https://doi.org/10.1021/acs.nanolett.6b00722

Guo Y, Wang S, Ruan K et al (2021) Highly thermally conductive carbon nanotubes pillared exfoliated graphite/polyimide composites. npj Flex Electron 5:16. https://doi.org/10.1038/s41528-021-00113-z

Shen X, Zheng Q, Kim J-K (2021) Rational design of two-dimensional nanofillers for polymer nanocomposites toward multifunctional applications. Prog Mater Sci 115:100708. https://doi.org/10.1016/j.pmatsci.2020.100708

Lian G, Tuan C-C, Li L et al (2016) Vertically aligned and interconnected graphene networks for high thermal conductivity of epoxy composites with ultralow loading. Chem Mater 28:6096–6104. https://doi.org/10.1021/acs.chemmater.6b01595

Li XH, Liu P, Li X et al (2018) Vertically aligned, ultralight and highly compressive all-graphitized graphene aerogels for highly thermally conductive polymer composites. Carbon 140:624–633. https://doi.org/10.1016/j.carbon.2018.09.016

Li Q, Guo Y, Li W et al (2014) Ultrahigh thermal conductivity of assembled aligned multilayer graphene/epoxy composite. Chem Mater 26:4459–4465. https://doi.org/10.1021/cm501473t

Zhang Y, Ren Y, Bai S (2018) Vertically aligned graphene film/epoxy composites as heat dissipating materials. Int J Heat Mass Transf 118:510–517. https://doi.org/10.1016/j.ijheatmasstransfer.2017.11.014

Shen X, Wang Z, Wu Y et al (2018) A three-dimensional multilayer graphene web for polymer nanocomposites with exceptional transport properties and fracture resistance. Mater Horiz 5:275–284. https://doi.org/10.1039/C7MH00984D

Wu S, Ladani RB, Zhang J et al (2015) Aligning multilayer graphene flakes with an external electric field to improve multifunctional properties of epoxy nanocomposites. Carbon 94:607–618. https://doi.org/10.1016/j.carbon.2015.07.026

Yan H, Wang R, Li Y, Long W (2015) Thermal conductivity of magnetically aligned graphene–polymer composites with Fe3O4-decorated graphene nanosheets. J Electron Mater 44:658–666. https://doi.org/10.1007/s11664-014-3561-z

Saeidijavash M, Garg J, Grady B et al (2017) High thermal conductivity through simultaneously aligned polyethylene lamellae and graphene nanoplatelets. Nanoscale 9:12867–12873. https://doi.org/10.1039/C7NR04686C

Shtein M, Nadiv R, Buzaglo M et al (2015) Thermally conductive graphene-polymer composites: size, percolation, and synergy effects. Chem Mater 27:2100–2106. https://doi.org/10.1021/cm504550e

Wu Z, Xu C, Ma C et al (2019) Synergistic effect of aligned graphene nanosheets in graphene foam for high-performance thermally conductive composites. Adv Mater 31:1900199. https://doi.org/10.1002/adma.201900199

Kargar F, Barani Z, Salgado R et al (2018) Thermal percolation threshold and thermal properties of composites with high loading of graphene and boron nitride fillers. ACS Appl Mater Interfaces 10:37555–37565. https://doi.org/10.1021/acsami.8b16616

Kim HS, Kim JH, Kim WY et al (2017) Volume control of expanded graphite based on inductively coupled plasma and enhanced thermal conductivity of epoxy composite by formation of the filler network. Carbon 119:40–46. https://doi.org/10.1016/j.carbon.2017.04.013

Shenogina N, Shenogin S, Xue L, Keblinski P (2005) On the lack of thermal percolation in carbon nanotube composites. Appl Phys Lett 87:133106. https://doi.org/10.1063/1.2056591

Kargar F, Barani Z, Balinskiy M et al (2019) Dual-functional graphene composites for electromagnetic shielding and thermal management. Adv Electron Mater 5:1800558. https://doi.org/10.1002/aelm.201800558

Liu Z, Chen Y, Li Y et al (2019) Graphene foam-embedded epoxy composites with significant thermal conductivity enhancement. Nanoscale 11:17600–17606. https://doi.org/10.1039/C9NR03968F

Bonnet P, Sireude D, Garnier B, Chauvet O (2007) Thermal properties and percolation in carbon nanotube-polymer composites. Appl Phys Lett 91:201910. https://doi.org/10.1063/1.2813625

Haggenmueller R, Guthy C, Lukes JR et al (2007) Single wall carbon nanotube/polyethylene nanocomposites: thermal and electrical conductivity. Macromolecules 40:2417–2421. https://doi.org/10.1021/ma0615046

Xiang J, Drzal LT (2011) Investigation of exfoliated graphite nanoplatelets (xGnP) in improving thermal conductivity of paraffin wax-based phase change material. Sol Energy Mater Sol Cells 95:1811–1818. https://doi.org/10.1016/j.solmat.2011.01.048

Gu J, Xie C, Li H et al (2014) Thermal percolation behavior of graphene nanoplatelets/polyphenylene sulfide thermal conductivity composites. Polym Compos 35:1087–1092. https://doi.org/10.1002/pc.22756

Wu H, Drzal LT (2013) High thermally conductive graphite nanoplatelet/polyetherimide composite by precoating: Effect of percolation and particle size. Polym Compos 34:2148–2153. https://doi.org/10.1002/pc.22624

Si W, Sun J, He X et al (2020) Enhancing thermal conductivity via conductive network conversion from high to low thermal dissipation in polydimethylsiloxane composites. J Mater Chem C 8:3463–3475. https://doi.org/10.1039/C9TC06968B

Bigg DM (1995) Thermal conductivity of heterophase polymer compositions. Thermal and electrical conductivity of polymer materials. Springer, Berlin Heidelberg, Berlin, Heidelberg, pp 1–30

Ruan K, Shi X, Guo Y, Gu J (2020) Interfacial thermal resistance in thermally conductive polymer composites: a review. Compos Commun 22:100518. https://doi.org/10.1016/j.coco.2020.100518

Novoselov KS, Jiang Z, Zhang Y et al (2007) Room-temperature quantum hall effect in graphene. Science 315:1379. https://doi.org/10.1126/science.1137201

Eda G, Chhowalla M (2010) Chemically derived graphene oxide: towards large-area thin-film electronics and optoelectronics. Adv Mater 22:2392–2415. https://doi.org/10.1002/adma.200903689

Mattevi C, Eda G, Agnoli S et al (2009) Evolution of electrical, chemical, and structural properties of transparent and conducting chemically derived graphene thin films. Adv Funct Mater 19:2577–2583. https://doi.org/10.1002/adfm.200900166

Huang JC (2002) Carbon black filled conducting polymers and polymer blends. Adv Polym Technol 21:299–313. https://doi.org/10.1002/adv.10025

Toker D, Azulay D, Shimoni N et al (2003) Tunneling and percolation in metal-insulator composite materials. Phys Rev B - Condens Matter Mater Phys 68:1–4. https://doi.org/10.1103/PhysRevB.68.041403

Meng Q, Han S, Araby S et al (2019) Mechanically robust, electrically and thermally conductive graphene-based epoxy adhesives. J Adhes Sci Technol 33:1337–1356. https://doi.org/10.1080/01694243.2019.1595890

Li Y, Zhang H, Porwal H et al (2017) Mechanical, electrical and thermal properties of in-situ exfoliated graphene/epoxy nanocomposites. Compos Part A Appl Sci Manuf 95:229–236. https://doi.org/10.1016/j.compositesa.2017.01.007

Wajid AS, Ahmed HST, Das S et al (2013) High-performance pristine graphene/epoxy composites with enhanced mechanical and electrical properties. Macromol Mater Eng 298:339–347. https://doi.org/10.1002/mame.201200043

Hsiao M-C, Ma C-CM, Chiang J-C et al (2013) Thermally conductive and electrically insulating epoxy nanocomposites with thermally reduced graphene oxide–silica hybrid nanosheets. Nanoscale 5:5863–5871. https://doi.org/10.1039/C3NR01471A

Wang Y, Weng GJ (2018) Electrical conductivity of carbon nanotube- and graphene-based nanocomposites. In: Meguid SA, Weng GJ (eds) Micromechanics and nanomechanics of composite solids. Springer International Publishing, Cham, pp 123–156

Marsden AJ, Papageorgiou DG, Vallés C et al (2018) Electrical percolation in graphene-polymer composites. 2D Mater 5:. https://doi.org/10.1088/2053-1583/aac055

Kernin A, Wan K, Liu Y et al (2019) The effect of graphene network formation on the electrical, mechanical, and multifunctional properties of graphene/epoxy nanocomposites. Compos Sci Technol 169:224–231. https://doi.org/10.1016/j.compscitech.2018.10.036

Meng Q, Jin J, Wang R et al (2014) Processable 3-nm thick graphene platelets of high electrical conductivity and their epoxy composites. Nanotechnology 25:125707. https://doi.org/10.1088/0957-4484/25/12/125707

Lu C, Mai Y-W (2005) Influence of aspect ratio on barrier properties of polymer-clay nanocomposites. Phys Rev Lett 95:88303. https://doi.org/10.1103/PhysRevLett.95.088303

AR Ravindran C Feng S Huang et al 2018 Effects of graphene nanoplatelet size and surface area on the AC electrical conductivity and dielectric constant of epoxy nanocomposites Polymers 10 https://doi.org/10.3390/polym10050477

Ounaies Z, Park C, Wise KE et al (2003) Electrical properties of single wall carbon nanotube reinforced polyimide composites. Compos Sci Technol 63:1637–1646. https://doi.org/10.1016/S0266-3538(03)00067-8

Weber M, Kamal MR (1997) Estimation of the volume resistivity of electrically conductive composites. Polym Compos 18:711–725. https://doi.org/10.1002/pc.10324

Zhang W, Dehghani-Sanij AA, Blackburn RS (2007) Carbon based conductive polymer composites. J Mater Sci 42:3408–3418. https://doi.org/10.1007/s10853-007-1688-5

Xia X, Wang Y, Zhong Z, Weng GJ (2016) A theory of electrical conductivity, dielectric constant, and electromagnetic interference shielding for lightweight graphene composite foams. J Appl Phys 120:85102. https://doi.org/10.1063/1.4961401

Polley MH, Boonstra BBST (1957) Carbon blacks for highly conductive rubber. Rubber Chem Technol 30:170–179. https://doi.org/10.5254/1.3542660

Gau C, Kuo C-Y, Ko HS (2009) Electron tunneling in carbon nanotube composites. Nanotechnology 20:395705. https://doi.org/10.1088/0957-4484/20/39/395705

Nieves CA, Ramos I, Pinto NJ, Zimbovskaya NA (2016) Electron transport mechanisms in polymer-carbon sphere composites. J Appl Phys 120:1–8. https://doi.org/10.1063/1.4955166

Kim SY, Noh YJ, Yu J (2015) Prediction and experimental validation of electrical percolation by applying a modified micromechanics model considering multiple heterogeneous inclusions. Compos Sci Technol 106:156–162. https://doi.org/10.1016/j.compscitech.2014.11.015

Zare Y, Rhee KY (2017) Development of a model for electrical conductivity of polymer/graphene nanocomposites assuming interphase and tunneling regions in conductive networks. Ind Eng Chem Res 56:9107–9115. https://doi.org/10.1021/acs.iecr.7b01348

ASTM (2014) ASTM D638–14, standard test method for tensile properties of plastics. In: ASTM Int. West Conshohocken, PA

Meng Q, Wu H, Zhao Z et al (2017) Free-standing, flexible, electrically conductive epoxy/graphene composite films. Compos Part A Appl Sci Manuf 92:42–50. https://doi.org/10.1016/j.compositesa.2016.10.028

Wan Y-J, Tang L-C, Yan D et al (2013) Improved dispersion and interface in the graphene/epoxy composites via a facile surfactant-assisted process. Compos Sci Technol 82:60–68. https://doi.org/10.1016/j.compscitech.2013.04.009

Wan Y-J, Gong L-X, Tang L-C et al (2014) Mechanical properties of epoxy composites filled with silane-functionalized graphene oxide. Compos Part A Appl Sci Manuf 64:79–89. https://doi.org/10.1016/j.compositesa.2014.04.023

Han S, Meng Q, Qiu Z et al (2019) Mechanical, toughness and thermal properties of 2D material-reinforced epoxy composites Polymer 184 https://doi.org/10.1016/j.polymer.2019.121884

Alves LO, Kawachi EY, Cassu SN (2019) An insight into molecular relaxation of organic-inorganic hybrids based on epoxy resin. Polym Test 78:105977. https://doi.org/10.1016/j.polymertesting.2019.105977

Tang L-C, Wan Y-J, Yan D et al (2013) The effect of graphene dispersion on the mechanical properties of graphene/epoxy composites. Carbon 60:16–27. https://doi.org/10.1016/j.carbon.2013.03.050

ASTM (2010) ASTM D790–10, standard test methods for flexural properties of unreinforced and reinforced plastics and electrical insulating materials. In: ASTM Int. West Conshohocken, PA

Alasvand Zarasvand K, Golestanian H (2017) Investigating the effects of number and distribution of GNP layers on graphene reinforced polymer properties: physical, numerical and micromechanical methods. Compos Sci Technol 139:117–126. https://doi.org/10.1016/j.compscitech.2016.12.024

ASTM (2015) ASTM D695–15, standard test method for compressive properties of rigid plastics. In: ASTM Int. West Conshohocken, PA

Arnebold A, Hartwig A (2016) Fast switchable, epoxy based shape-memory polymers with high strength and toughness. Polymer 83:40–49. https://doi.org/10.1016/j.polymer.2015.12.007

Koo B, Subramanian N, Chattopadhyay A (2016) Molecular dynamics study of brittle fracture in epoxy-based thermoset polymer. Compos Part B Eng 95:433–439. https://doi.org/10.1016/j.compositesb.2016.04.012

Park YT, Qian Y, Chan C et al (2015) Epoxy toughening with low graphene loading. Adv Funct Mater 25:575–585. https://doi.org/10.1002/adfm.201402553

Atif R, Shyha I, Inam F (2016) Mechanical, thermal, and electrical properties of graphene-epoxy nanocomposites-a review Polymers 8 https://doi.org/10.3390/polym8080281

Meng Q, Araby S, Ma J (2015) Toughening mechanisms in epoxy/graphene platelets composites

Wang J, Jin X, Li C et al (2019) Graphene and graphene derivatives toughening polymers: toward high toughness and strength. Chem Eng J 370:831–854. https://doi.org/10.1016/j.cej.2019.03.229

Chandrasekaran S, Sato N, Tölle F et al (2014) Fracture toughness and failure mechanism of graphene based epoxy composites. Compos Sci Technol 97:90–99. https://doi.org/10.1016/j.compscitech.2014.03.014

Zaman I, Phan TT, Kuan H-C et al (2011) Epoxy/graphene platelets nanocomposites with two levels of interface strength. Polymer 52:1603–1611. https://doi.org/10.1016/j.polymer.2011.02.003

Han S, Chand A, Araby S et al (2019) Thermally and electrically conductive multifunctional sensor based on epoxy/graphene composite. Nanotechnology 31:75702. https://doi.org/10.1088/1361-6528/ab5042

Moriche R, Sánchez M, Jiménez-Suárez A et al (2016) Strain monitoring mechanisms of sensors based on the addition of graphene nanoplatelets into an epoxy matrix. Compos Sci Technol 123:65–70. https://doi.org/10.1016/j.compscitech.2015.12.002

Embrey L, Nautiyal P, Loganathan A et al (2017) Three-dimensional graphene foam induces multifunctionality in epoxy nanocomposites by simultaneous improvement in mechanical, thermal, and electrical properties. ACS Appl Mater Interfaces 9:39717–39727. https://doi.org/10.1021/acsami.7b14078

Stavropoulos SG, Sanida A, Psarras GC (2021) Carbon allotropes/epoxy nanocomposites as capacitive energy storage/harvesting systems. Appl Sci 11. https://doi.org/10.3390/app11157059

Yang C, Wei H, Guan L et al (2015) Polymer nanocomposites for energy storage, energy saving, and anticorrosion. J Mater Chem A 3:14929–14941. https://doi.org/10.1039/C5TA02707A

Barani Z, Kargar F, Godziszewski K et al (2020) Graphene epoxy-based composites as efficient electromagnetic absorbers in the extremely high-frequency band. ACS Appl Mater Interfaces 12:28635–28644. https://doi.org/10.1021/acsami.0c06729

Huangfu Y, Liang C, Han Y et al (2019) Fabrication and investigation on the Fe3O4/thermally annealed graphene aerogel/epoxy electromagnetic interference shielding nanocomposites. Compos Sci Technol 169:70–75. https://doi.org/10.1016/j.compscitech.2018.11.012

Su Z, Wang H, Tian K et al (2018) The combination of π-π interaction and covalent bonding can synergistically strengthen the flexible electrical insulating nanocomposites with well adhesive properties and thermal conductivity. Compos Sci Technol 155:1–10. https://doi.org/10.1016/j.compscitech.2017.09.018

Ghori SW, Siakeng R, Rasheed M et al (2018) 2 - The role of advanced polymer materials in aerospace. In: Jawaid M, Thariq M (eds) Sustainable composites for aerospace applications. Woodhead Publishing, pp 19–34

Guadagno L, Naddeo C, Raimondo M et al (2017) Influence of carbon nanoparticles/epoxy matrix interaction on mechanical, electrical and transport properties of structural advanced materials. Nanotechnology 28:94001. https://doi.org/10.1088/1361-6528/aa583d

Chatterjee S, Nafezarefi F, Tai NH et al (2012) Size and synergy effects of nanofiller hybrids including graphene nanoplatelets and carbon nanotubes in mechanical properties of epoxy composites. Carbon 50:5380–5386. https://doi.org/10.1016/j.carbon.2012.07.021

Tien DH, Park J, Han SA et al (2011) Electrical and thermal conductivities of stycast 1266 epoxy/graphite composites. J Korean Phys Soc 59:2760–2764. https://doi.org/10.3938/jkps.59.2760

Serena Saw WP, Mariatti M (2012) Properties of synthetic diamond and graphene nanoplatelet-filled epoxy thin film composites for electronic applications. J Mater Sci Mater Electron 23:817–824. https://doi.org/10.1007/s10854-011-0499-2

Prolongo SG, Moriche R, Del Rosario G et al (2016) Joule effect self-heating of epoxy composites reinforced with graphitic nanofillers. J Polym Res 23:189. https://doi.org/10.1007/s10965-016-1092-4

Li A, Zhang C, Zhang Y-F (2017) Graphene nanosheets-filled epoxy composites prepared by a fast dispersion method. J Appl Polym Sci 134:45152. https://doi.org/10.1002/app.45152

Zakaria MR, Abdul Kudus MH, Md. Akil H, Mohd Thirmizir MZ (2017) Comparative study of graphene nanoparticle and multiwall carbon nanotube filled epoxy nanocomposites based on mechanical, thermal and dielectric properties. Compos Part B Eng 119:57–66. https://doi.org/10.1016/j.compositesb.2017.03.023

Zakaria MR, Abdul Kudus MH, Md Akil H et al (2019) Comparative study of single-layer graphene and single-walled carbon nanotube-filled epoxy nanocomposites based on mechanical and thermal properties. Polym Compos 40:E1840–E1849. https://doi.org/10.1002/pc.25173

Jia J, Sun X, Lin X et al (2014) Exceptional electrical conductivity and fracture resistance of 3D interconnected graphene foam/epoxy composites. ACS Nano 8:5774–5783. https://doi.org/10.1021/nn500590g

Liu Z, Shen D, Yu J et al (2016) Exceptionally high thermal and electrical conductivity of three-dimensional graphene-foam-based polymer composites. RSC Adv 6:22364–22369. https://doi.org/10.1039/C5RA27223H

Song P, Liang C, Wang L et al (2019) Obviously improved electromagnetic interference shielding performances for epoxy composites via constructing honeycomb structural reduced graphene oxide. Compos Sci Technol 181:107698. https://doi.org/10.1016/j.compscitech.2019.107698

Sun Y, He Y, Tang B et al (2017) Influence from the types of surface functional groups of RGO on the performances of thermal interface materials. RSC Adv 7:55790–55795. https://doi.org/10.1039/C7RA12034F

Chen H, Ginzburg VV, Yang J et al (2016) Thermal conductivity of polymer-based composites: fundamentals and applications. Prog Polym Sci 59:41–85. https://doi.org/10.1016/j.progpolymsci.2016.03.001

Huang X, Zhi C, Lin Y et al (2020) Thermal conductivity of graphene-based polymer nanocomposites. Mater Sci Eng R Reports 142:100577. https://doi.org/10.1016/j.mser.2020.100577

Ruan K, Guo Y, Lu C et al (2021) Significant reduction of interfacial thermal resistance and phonon scattering in graphene/polyimide thermally conductive composite films for thermal management. Research 2021:8438614. https://doi.org/10.34133/2021/8438614

Guo Y, Xu G, Yang X et al (2018) Significantly enhanced and precisely modeled thermal conductivity in polyimide nanocomposites with chemically modified graphene via in situ polymerization and electrospinning-hot press technology. J Mater Chem C 6:3004–3015. https://doi.org/10.1039/C8TC00452H

Qiu L, Zou H, Wang X et al (2019) Enhancing the interfacial interaction of carbon nanotubes fibers by Au nanoparticles with improved performance of the electrical and thermal conductivity. Carbon 141:497–505. https://doi.org/10.1016/j.carbon.2018.09.073

Wei D, Liu Y, Wang Y et al (2009) Synthesis of N-doped graphene by chemical vapor deposition and its electrical properties. Nano Lett 9:1752–1758. https://doi.org/10.1021/nl803279t

Georgakilas V, Otyepka M, Bourlinos AB et al (2012) Functionalization of graphene: covalent and non-covalent approaches, derivatives and applications. Chem Rev 112:6156–6214. https://doi.org/10.1021/cr3000412

Ahmadi-Moghadam B, Sharafimasooleh M, Shadlou S, Taheri F (2015) Effect of functionalization of graphene nanoplatelets on the mechanical response of graphene/epoxy composites. Mater Des 66:142–149. https://doi.org/10.1016/j.matdes.2014.10.047

Wang X, Xing W, Zhang P et al (2012) Covalent functionalization of graphene with organosilane and its use as a reinforcement in epoxy composites. Compos Sci Technol 72:737–743. https://doi.org/10.1016/j.compscitech.2012.01.027

Depaifve S, Federico CE, Ruch D et al (2020) Nitrene functionalization as a new approach for reducing the interfacial thermal resistance in graphene nanoplatelets/epoxy nanocomposites. Carbon 167:646–657. https://doi.org/10.1016/j.carbon.2020.06.035

Wang Y, Zhan HF, Xiang Y et al (2015) Effect of covalent functionalization on thermal transport across graphene–polymer interfaces. J Phys Chem C 119:12731–12738. https://doi.org/10.1021/acs.jpcc.5b02920

Tang G, Jiang Z-G, Li X et al (2014) Electrically conductive rubbery epoxy/diamine-functionalized graphene nanocomposites with improved mechanical properties. Compos Part B Eng 67:564–570. https://doi.org/10.1016/j.compositesb.2014.08.013

Gu J, Yang X, Lv Z et al (2016) Functionalized graphite nanoplatelets/epoxy resin nanocomposites with high thermal conductivity. Int J Heat Mass Transf 92:15–22. https://doi.org/10.1016/j.ijheatmasstransfer.2015.08.081

Ji X, Xu Y, Zhang W et al (2016) Review of functionalization, structure and properties of graphene/polymer composite fibers. Compos Part A Appl Sci Manuf 87:29–45. https://doi.org/10.1016/j.compositesa.2016.04.011

Cao L, Liu X, Na H et al (2013) How a bio-based epoxy monomer enhanced the properties of diglycidyl ether of bisphenol A ( DGEBA)/graphene composites. J Mater Chem A 1:5081–5088. https://doi.org/10.1039/c3ta01700a

Teng CC, Ma CCM, Lu CH et al (2011) Thermal conductivity and structure of non-covalent functionalized graphene/epoxy composites. Carbon 49:5107–5116. https://doi.org/10.1016/j.carbon.2011.06.095

Fang Q, Shen Y, Chen B (2015) Synthesis, decoration and properties of three-dimensional graphene-based macrostructures: a review. Chem Eng J 264:753–771. https://doi.org/10.1016/j.cej.2014.12.001

Kaur M, Kaur M, Sharma VK (2018) Nitrogen-doped graphene and graphene quantum dots: a review onsynthesis and applications in energy, sensors and environment. Adv Colloid Interface Sci 259:44–64. https://doi.org/10.1016/j.cis.2018.07.001

Liang H-W, Zhuang X, Brüller S et al (2014) Hierarchically porous carbons with optimized nitrogen doping as highly active electrocatalysts for oxygen reduction. Nat Commun 5:4973. https://doi.org/10.1038/ncomms5973

Aghamohammadi H, Hassanzadeh N, Eslami-Farsani R (2021) A review study on the recent advances in developing the heteroatom-doped graphene and porous graphene as superior anode materials for Li-ion batteries. Ceram Int 47:22269–22301. https://doi.org/10.1016/j.ceramint.2021.05.048

Mou Z, Wu Y, Sun J et al (2014) TiO2 nanoparticles-functionalized N-doped graphene with superior interfacial contact and enhanced charge separation for photocatalytic hydrogen generation. ACS Appl Mater Interfaces 6:13798–13806. https://doi.org/10.1021/am503244w

Wang X, Shi G (2015) An introduction to the chemistry of graphene. Phys Chem Chem Phys 17:28484–28504. https://doi.org/10.1039/C5CP05212B

Sun Z, Yan Z, Yao J et al (2010) Growth of graphene from solid carbon sources. Nature 468:549–552. https://doi.org/10.1038/nature09579

Mortazavi B, Rajabpour A, Ahzi S et al (2012) Nitrogen doping and curvature effects on thermal conductivity of graphene: a non-equilibrium molecular dynamics study. Solid State Commun 152:261–264. https://doi.org/10.1016/j.ssc.2011.11.035

Yang H, Tang Y, Liu Y et al (2014) Thermal conductivity of graphene nanoribbons with defects and nitrogen doping. React Funct Polym 79:29–35. https://doi.org/10.1016/j.reactfunctpolym.2014.03.006

Wang X, Sun G, Routh P et al (2014) Heteroatom-doped graphene materials: syntheses, properties and applications. Chem Soc Rev 43:7067–7098. https://doi.org/10.1039/C4CS00141A

Shahzad F, Kumar P, Yu S et al (2015) Sulfur-doped graphene laminates for EMI shielding applications. J Mater Chem C 3:9802–9810. https://doi.org/10.1039/C5TC02166A

Huang Y, Wu D, Dianat A et al (2017) Bipolar nitrogen-doped graphene frameworks as high-performance cathodes for lithium ion batteries. J Mater Chem A 5:1588–1594. https://doi.org/10.1039/C6TA09161J

Beckert M, Tölle FJ, Bruchmann B, Mülhaupt R (2015) Nitrogen-doped multilayer graphene as functional filler for carbon/polyamide 12 nanocomposites. Macromol Mater Eng 300:785–792. https://doi.org/10.1002/mame.201500020

Pu N-W, Peng Y-Y, Wang P-C et al (2014) Application of nitrogen-doped graphene nanosheets in electrically conductive adhesives. Carbon 67:449–456. https://doi.org/10.1016/j.carbon.2013.10.017

Tschoppe K, Beckert F, Beckert M, Mülhaupt R (2015) Thermally reduced graphite oxide and mechanochemically functionalized graphene as functional fillers for epoxy nanocomposites. Macromol Mater Eng 300:140–152. https://doi.org/10.1002/mame.201400245

Lin S, Ju S, Shi G et al (2019) Ultrathin nitrogen-doping graphene films for flexible and stretchable EMI shielding materials. J Mater Sci 54:7165–7179. https://doi.org/10.1007/s10853-019-03372-4

Qing Y, Li Y, Luo F (2020) Electromagnetic interference shielding properties of nitrogen-doped graphene/epoxy composites. J Mater Sci Mater Electron. https://doi.org/10.1007/s10854-020-03938-y

Guo W, Wang X, Gangireddy CSR et al (2019) Cardanol derived benzoxazine in combination with boron-doped graphene toward simultaneously improved toughening and flame retardant epoxy composites. Compos Part A Appl Sci Manuf 116:13–23. https://doi.org/10.1016/j.compositesa.2018.10.010

Feng Y, He C, Wen Y et al (2018) Superior flame retardancy and smoke suppression of epoxy-based composites with phosphorus/nitrogen co-doped graphene. J Hazard Mater 346:140–151. https://doi.org/10.1016/j.jhazmat.2017.12.019

Ma P-C, Siddiqui NA, Marom G, Kim J-K (2010) Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: a review. Compos Part A Appl Sci Manuf 41:1345–1367. https://doi.org/10.1016/j.compositesa.2010.07.003

Hwang S-H, Park Y-B, Yoon KH, Bang DS (2011) Smart materials and structures based on carbon nanotube composites. In: Yellampalli S (ed) Carbon nanotubes. IntechOpen, Rijeka

Imran KA, Shivakumar KN (2018) Enhancement of electrical conductivity of epoxy using graphene and determination of their thermo-mechanical properties. J Reinf Plast Compos 37:118–133. https://doi.org/10.1177/0731684417736143

Chang H, Liu H, Tan C (2015) Using supercritical Co2-assisted mixing to prepare graphene/carbon nanotube/epoxy nanocomposites. Polymer 75:125–133

Poutrel Q-A, Wang Z, Wang D et al (2017) Effect of pre and post-dispersion on electro-thermo-mechanical properties of a graphene enhanced epoxy. Appl Compos Mater 24:313–336. https://doi.org/10.1007/s10443-016-9541-0

Yang S-Y, Lin W-N, Huang Y-L et al (2011) Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 49:793–803. https://doi.org/10.1016/j.carbon.2010.10.014

He Z, Zhang X, Chen M et al (2013) Effect of the filler structure of carbon nanomaterials on the electrical, thermal, and rheological properties of epoxy composites. J Appl Polym Sci 129:3366–3372. https://doi.org/10.1002/app.39096

Messina E, Leone N, Foti A et al (2016) Double-wall nanotubes and graphene nanoplatelets for hybrid conductive adhesives with enhanced thermal and electrical conductivity. ACS Appl Mater Interfaces 8:23244–23259. https://doi.org/10.1021/acsami.6b06145

Prolongo SG, Redondo O, Campo M, Ureña A (2019) Heat dissipation on electrical conductor composites by combination of carbon nanotubes and graphene nanoplatelets. J Coatings Technol Res 16:491–498. https://doi.org/10.1007/s11998-018-0127-7

Prolongo SG, Moriche R, Ureña A et al (2018) Carbon nanotubes and graphene into thermosetting composites: Synergy and combined effect. J Appl Polym Sci 135:46475. https://doi.org/10.1002/app.46475

Wang B, Dou S, Li W, Gao Y (2020) Multifunctional reduced graphene oxide/carbon nanotubes/epoxy resin nanocomposites based on carbon nanohybrid preform. Soft Mater 18:89–100. https://doi.org/10.1080/1539445X.2019.1688833

Ji C, Yan C, Wang Y et al (2019) Thermal conductivity enhancement of CNT/MoS2/graphene–epoxy nanocomposites based on structural synergistic effects and interpenetrating network. Compos Part B Eng 163:363–370. https://doi.org/10.1016/j.compositesb.2018.11.005

Liang C, Song P, Ma A et al (2019) Highly oriented three-dimensional structures of Fe3O4 decorated CNTs/reduced graphene oxide foam/epoxy nanocomposites against electromagnetic pollution. Compos Sci Technol 181:107683. https://doi.org/10.1016/j.compscitech.2019.107683

Zhang K, Zhang Y, Wang S (2013) Effectively decoupling electrical and thermal conductivity of polymer composites. Carbon 65:105–111. https://doi.org/10.1016/j.carbon.2013.08.005

Bo T, Zhengwei W, Huang W et al (2017) RGO and three-dimensional graphene networks co-modified TIMs with high performances. Nanoscale Res Lett 12:527. https://doi.org/10.1186/s11671-017-2298-z

An F, Li X, Min P et al (2018) Vertically aligned high-quality graphene foams for anisotropically conductive polymer composites with ultrahigh through-plane thermal conductivities. ACS Appl Mater Interfaces 10:17383–17392. https://doi.org/10.1021/acsami.8b04230

Liang C, Qiu H, Han Y et al (2019) Superior electromagnetic interference shielding 3D graphene nanoplatelets/reduced graphene oxide foam/epoxy nanocomposites with high thermal conductivity. J Mater Chem C 7:2725–2733. https://doi.org/10.1039/C8TC05955A

Krieg AS, King JA, Jaszczak DC et al (2018) Tensile and conductivity properties of epoxy composites containing carbon black and graphene nanoplatelets. J Compos Mater 52:3909–3918. https://doi.org/10.1177/0021998318771460

Ohayon-Lavi A, Buzaglo M, Ligati S et al (2020) Compression-enhanced thermal conductivity of carbon loaded polymer composites. Carbon 163:333–340. https://doi.org/10.1016/j.carbon.2020.03.026

Ma X, Wang W, Qi X et al (2021) Highly thermally conductive epoxy composites with anti-friction performance achieved by carbon nanofibers assisted graphene nanoplatelets assembly. Eur Polym J 151:110443. https://doi.org/10.1016/j.eurpolymj.2021.110443

Sun Y, Yin Y, Mayers BT et al (2002) Uniform silver nanowires synthesis by reducing AgNO3 with ethylene glycol in the presence of seeds and poly(vinyl pyrrolidone). Chem Mater 14:4736–4745. https://doi.org/10.1021/cm020587b

Skrabalak SE, Wiley BJ, Kim M et al (2008) On the polyol synthesis of silver nanostructures: glycolaldehyde as a reducing agent. Nano Lett 8:2077–2081. https://doi.org/10.1021/nl800910d

Chou T, Tsai H, Hsu C, Yip M (2018) Fabrication and characteristics of graphene-reinforced silver nanowire/polybenzoxazine/epoxy copolymer composite thin films. Polym Int 67:1081–1093. https://doi.org/10.1002/pi.5614

Zhang L, Zhu W, Huang Y, Qi S (2019) Synergetic effects of silver nanowires and graphene oxide on thermal conductivity of epoxy composites Nanomaterials 9. https://doi.org/10.3390/nano9091264

Zhang Z, Li W, Wang X et al (2019) Low effective content of reduced graphene oxide/silver nanowire hybrids in epoxy composites with enhanced conductive properties. J Mater Sci Mater Electron 30:7384–7392. https://doi.org/10.1007/s10854-019-01050-4

Barani Z, Mohammadzadeh A, Geremew A et al (2020) Thermal properties of the binary-filler hybrid composites with graphene and copper nanoparticles. Adv Funct Mater 30:1904008. https://doi.org/10.1002/adfm.201904008

Yang X, Fan S, Li Y et al (2020) Synchronously improved electromagnetic interference shielding and thermal conductivity for epoxy nanocomposites by constructing 3D copper nanowires/thermally annealed graphene aerogel framework. Compos Part A Appl Sci Manuf 128:105670. https://doi.org/10.1016/j.compositesa.2019.105670

Huang Z, Wang T, Zhang X et al (2016) Preparation of tourmaline/graphene oxide and its application in thermal interface materials. J Compos Mater 50:3953–3960. https://doi.org/10.1177/0021998316630393

Jiang Y, Sun R, Zhang H-B et al (2017) Graphene-coated ZnO tetrapod whiskers for thermally and electrically conductive epoxy composites. Compos Part A Appl Sci Manuf 94:104–112. https://doi.org/10.1016/j.compositesa.2016.12.009

Aradhana R, Mohanty S, Nayak SK (2019) Novel electrically conductive epoxy/reduced graphite oxide/silica hollow microspheres adhesives with enhanced lap shear strength and thermal conductivity. Compos Sci Technol 169:86–94. https://doi.org/10.1016/j.compscitech.2018.11.008

Lewis JS, Barani Z, Magana AS et al (2019) Thermal and electrical conductivity control in hybrid composites with graphene and boron nitride fillers. Mater Res Express 6:85325. https://doi.org/10.1088/2053-1591/ab2215

Wang S, Cao M, Cong F et al (2021) Mechanical and thermal properties of graphene and carbon nanotube reinforced epoxy/boron nitride adhesives. J Adhes Sci Technol 1 17. https://doi.org/10.1080/01694243.2021.1877017

Nouri-Borujerdi A, Kazemi-Ranjbar S (2021) Thermal and electrical conductivity of a graphene-based hybrid filler epoxy composite. J Mater Sci. https://doi.org/10.1007/s10853-021-06272-8

Pourrahimi AM, Hoang TA, Liu D et al (2016) Highly efficient interfaces in nanocomposites based on polyethylene and ZnO nano/hierarchical particles: a novel approach toward ultralow electrical conductivity insulations. Adv Mater 28:8651–8657. https://doi.org/10.1002/adma.201603291

Phiri J, Gane P, Maloney TC (2017) General overview of graphene: production, properties and application in polymer composites. Mater Sci Eng B 215:9–28

Kim J, Im H, Kim J, Kim J (2012) Thermal and electrical conductivity of Al(OH)3 covered graphene oxide nanosheet/epoxy composites. J Mater Sci 47:1418–1426. https://doi.org/10.1007/s10853-011-5922-9

Zong P, Fu J, Chen L et al (2016) Effect of aminopropylisobutyl polyhedral oligomeric silsesquioxane functionalized graphene on the thermal conductivity and electrical insulation properties of epoxy composites. RSC Adv 6:10498–10506. https://doi.org/10.1039/C5RA24885J

Zhao Y, Wu Z, Guo S et al (2022) Hyperbranched graphene oxide structure-based epoxy nanocomposite with simultaneous enhanced mechanical properties, thermal conductivity, and superior electrical insulation. Compos Sci Technol 217:109082. https://doi.org/10.1016/j.compscitech.2021.109082

Aradhana R, Mohanty S, Nayak SK (2018) Comparison of mechanical, electrical and thermal properties in graphene oxide and reduced graphene oxide filled epoxy nanocomposite adhesives. Polymer 141:109–123. https://doi.org/10.1016/j.polymer.2018.03.005

Jarosinski L, Rybak A, Gaska K et al (2017) Enhanced thermal conductivity of graphene nanoplatelets epoxy composites. Mater Sci Pol 35:382–389. https://doi.org/10.1515/msp-2017-0028

Huang C, Qian X, Yang R (2018) Thermal conductivity of polymers and polymer nanocomposites. Mater Sci Eng R Reports 132:1–22. https://doi.org/10.1016/j.mser.2018.06.002

Li M, Tang C, Zhang L et al (2018) A thermally conductive and insulating epoxy polymer composite with hybrid filler of modified copper nanowires and graphene oxide. J Mater Sci Mater Electron 29:4948–4954. https://doi.org/10.1007/s10854-017-8454-5

Han Y, Shi X, Yang X et al (2020) Enhanced thermal conductivities of epoxy nanocomposites via incorporating in-situ fabricated hetero-structured SiC-BNNS fillers. Compos Sci Technol 187:107944. https://doi.org/10.1016/j.compscitech.2019.107944

Zhang R-H, Shi X-T, Tang L et al (2020) Thermally conductive and insulating epoxy composites by synchronously incorporating si-sol functionalized glass fibers and boron nitride fillers. Chinese J Polym Sci 38:730–739. https://doi.org/10.1007/s10118-020-2391-0

Gu J, Ruan K (2021) Breaking through bottlenecks for thermally conductive polymer composites: a perspective for intrinsic thermal conductivity, interfacial thermal resistance and theoretics. Nano-Micro Lett 13:110. https://doi.org/10.1007/s40820-021-00640-4

Wu Z-S, Zhou G, Yin L-C et al (2012) Graphene/metal oxide composite electrode materials for energy storage. Nano Energy 1:107–131. https://doi.org/10.1016/j.nanoen.2011.11.001

Wang R, Zhuo D, Weng Z et al (2015) A novel nanosilica/graphene oxide hybrid and its flame retarding epoxy resin with simultaneously improved mechanical, thermal conductivity, and dielectric properties. J Mater Chem A 3:9826–9836. https://doi.org/10.1039/C5TA00722D

Pu X, Bin ZH, Li X et al (2014) Thermally conductive and electrically insulating epoxy nanocomposites with silica-coated graphene. RSC Adv 4:15297–15303. https://doi.org/10.1039/c4ra00518j

Du F, Yang W, Zhang F et al (2015) Enhancing the heat transfer efficiency in graphene–epoxy nanocomposites using a magnesium oxide–graphene hybrid structure. ACS Appl Mater Interfaces 7:14397–14403. https://doi.org/10.1021/acsami.5b03196

Sun R, Yao H, Bin ZH et al (2016) Decoration of defect-free graphene nanoplatelets with alumina for thermally conductive and electrically insulating epoxy composites. Compos Sci Technol 137:16–23. https://doi.org/10.1016/j.compscitech.2016.10.017

Pan Y-T, Wan J, Zhao X et al (2017) Interfacial growth of MOF-derived layered double hydroxide nanosheets on graphene slab towards fabrication of multifunctional epoxy nanocomposites. Chem Eng J 330:1222–1231. https://doi.org/10.1016/j.cej.2017.08.059

Fu J, Zong P, Chen L et al (2016) A facile approach to covalently functionalized graphene nanosheet hybrids and polymer nanocomposites. ChemNanoMat 2:830–839. https://doi.org/10.1002/cnma.201600131

Jiang J, Liu F, Zhuang K et al (2017) Composites of epoxy/graphene-modified-diamond filler show enhanced thermal conductivity and high electrical insulation. RSC Adv 7:40761–40766. https://doi.org/10.1039/C7RA07272D

Wang Y, Yu J, Dai W et al (2014) Epoxy composites filled with one-dimensional SiC nanowires-two-dimensional graphene nanoplatelets hybrid nanofillers. RSC Adv 4:59409–59417. https://doi.org/10.1039/c4ra07878k

He J, Wang H, Su Z et al (2019) Thermal conductivity and electrical insulation of epoxy composites with graphene-SiC nanowires and BaTiO3. Compos Part A Appl Sci Manuf 117:287–298. https://doi.org/10.1016/j.compositesa.2018.10.031

Shi X, Zhang R, Ruan K et al (2021) Improvement of thermal conductivities and simulation model for glass fabrics reinforced epoxy laminated composites via introducing hetero-structured BNN-30@BNNS fillers. J Mater Sci Technol 82:239–249. https://doi.org/10.1016/j.jmst.2021.01.018

Huang T, Zeng X, Yao Y et al (2016) Boron nitride@graphene oxide hybrids for epoxy composites with enhanced thermal conductivity. RSC Adv 6:35847–35854. https://doi.org/10.1039/C5RA27315C