Abstract

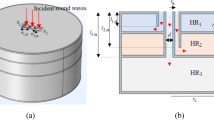

Sound absorbing elements commonly used to make quieter spaces are very desirable for high-frequency noise control. It is more attractive if it is possible to produce sound absorbing structures that perform well for a wide frequency range, especially in low-frequencies. In this regard, Helmholtz resonator array is a well-known structure but the maximum performance of each resonator unit in an array panel can only be achieved at resonance frequency that is dependent on its size. Therefore, a resonator array panel with equal size units has insufficient performance in a wide frequency range. Hence, the consideration of suitable sizes for each resonator in an array panel consisting of unequal size units is a key point to widen the frequency range of sound absorption. On the other hand, it seems that engineering science can be developed by nature inspiration. In addition, Fibonacci sequence is a famous mathematical model which describes the shape/ratio of different phenomena which exist in nature. In this paper, Fibonacci sequence is utilized to investigate Helmholtz resonator arrangement to increase both the amount of sound absorption coefficient and frequency bandwidth of absorption without changing the total volume of resonator array with equal size units. Analytical solutions based on the modified equivalent electrical circuit theory is used to calculate the sound absorption coefficient of the proposed panel with numerical experiments in MAPLE and COMSOL Multiphysics softwares to validate the proposed overall approach. Results show that the Fibonacci sequence is an optimum candidate to design a resonator-based sound absorber in low-frequency noise.

Similar content being viewed by others

References

Aiman N, Gulnaz S, Alena M. The characteristics of pollution in the big industrial cities of Kazakhstan by the example of Almaty. J Environ Health Sci Eng. 2018;16:81–8. https://doi.org/10.1007/s40201-018-0299-1.

Massoudinejad M, Amanidaz N, Santos RM, Bakhshoodeh R. Use of municipal, agricultural, industrial, construction and demolition waste in thermal and sound building insulation materials: a review article. J Environ Health Sci Eng. 2019;17:1227–42. https://doi.org/10.1007/s40201-019-00380-z.

Negahdari H, Javadpour S, Moattar F. Designing, constructing and testing of a new generation of sound barriers. J Environ Health Sci Eng. 2019;17:507–27. https://doi.org/10.1007/s40201-019-00357-y.

Erkaya S, Geymen A, Bostancı B. Modelling and evaluation of light railway system’s noise using neural predictors. J Environ Health Sci Eng. 2015;13:20. https://doi.org/10.1186/s40201-015-0173-3.

Jafari MJ, Sadeghian M, Khavanin A, Khodakarim S, Jafarpisheh AS. Effects of noise on mental performance and annoyance considering task difficulty level and tone components of noise. J Environ Health Sci Eng. 2019;17:353–65. https://doi.org/10.1007/s40201-019-00353-2.

Jafari MJ, Monazam MR, Kazempour M. Providing an optimal porous absorbent pattern to reduce mid to low-frequency sounds. J Environ Health Sci Eng. 2018;16:289–97. https://doi.org/10.1007/s40201-018-0317-3.

Basirjafari S, Malekfar R, Khadem SE. Low loading of carbon nanotubes to enhance acoustical properties of poly(ether)urethane foams. J Appl Phys. 2012;112:104312–1 8.

Basirjafari S. Effects of carbon nanotube loading on cellular structures and sound absorption of polyurethane foams. Micro Nano Lett. 2018;13(10):1501–5.

Kim BS, Park J. Double resonant porous structure backed by air cavity for low frequency sound absorption improvement. Compos Struct. 2017. https://doi.org/10.1016/j.compstruct.2017.06.027.

Zhao XD, Fan XQ. Enhancing low frequency sound absorption of microperforated panel absorbers by using mechanical impedance plates. Appl Acoust. 2015;88:123–8.

Broghany M, Basirjafari S, Saffar S. Optimization of flat multi-layer sound absorber by using multi-objective genetic algorithm for application in anechoic chamber. Modares Mech Eng. 2016;16(2):215–22 (in Persian).

Broghany M, Saffar S, Basirjafari S. Increasing of the frequency band of sound absorption for flat multi-layered absorbers consist of porous material, perforated panel and air-gap. Amirkabir J Mech Eng. 2018;50(1):75–7 (in Persian).

Sakagami K, Nagayama Y, Morimoto M, Yairi M. Pilot study on wideband sound absorber obtained by combination of two different microperforated (MPP) absorbers. Acoustic Sci Tech. 2009;30:154–6.

Ruiz H, Cobo P, Jacobsen F. Optimization of multiple-layer microperforated panels by simulated annealing. Appl Acoust. 2011;72(10):772–6.

Falsafi I, Ohadi A. Design guide of single layer micro perforated panel absorber with uniform air gap. Appl Acoust. 2017;126:48–57.

Yairi M, Sakagami K, Morimoto M, Minemura A. Acoustical properties of microperforated panel absorbers with various configurations of the back cavity. In12th International Congress on Sound and Vibration 2005.

Toyoda M, Takahashi D. Sound transmission through a microperforated-panel structure with subdivided air cavities. J Acoust Soc Am. 2008;124(6):3594–603.

Liu J, Herrin DW. Enhancing micro-perforated panel attenuation by partitioning the adjoining cavity. Appl Acoust. 2010;71(2):120–7.

Huang S, Li S, Wang X, Mao D. Micro-perforated absorbers with incompletely partitioned cavities. Appl Acoust. 2017;126:114–9.

Lu Y, Tang H, Wang Q, Tian J, Qu Y, Qiu B. The perforated panel resonator with flexible tube bundles and its Appliations. J Acoust Soc Am. 2008;123(5):2983.

Zhang Q, Lv YD, Yang J, Wei XW, Wang YQ. Experiment study on the sound absorption characteristic of perforated panel with ladder tube bundles. Noise Vib Cont. 2009;2:253–6.

Li D, Chang D, Liu B. Enhancing the low frequency sound absorption of a perforated panel by parallel-arranged extended tubes. Appl Acoust. 2016;102:126–32.

Wang C, Huang L. On the acoustic properties of parallel arrangement of multiple micro-perforated panel absorbers with different cavity depths. J Acoust Soc Am. 2011;130(1):208–18.

Wang C, Huang L, Zhang Y. Oblique incidence sound absorption of parallel arrangement of multiple micro-perforated panel absorbers in a periodic pattern. J Sound Vib. 2014;333(25):6828–42.

Guo W, Min H. A compound micro-perforated panel sound absorber with partitioned cavities of different depths. Energy Procedia. 2015;78:1617–22.

Tang Y, Ren S, Meng H, Xin F, Huang L, Chen T, et al. Hybrid acoustic metamaterial as super absorber for broadband low-frequency sound. Sci Rep. 2017;7:43340.

Park SH. Acoustic properties of micro-perforated panel absorbers backed by Helmholtz resonators for the improvement of low-frequency sound absorption. J Sound Vib. 2013;332(20):4895–911.

Seo SH, Kim YH. Silencer design by using array resonators for low-frequency band noise reduction. J Acoust Soc Am. 2005;118(4):2332–8.

Garrelick JM. The transmission loss of a wall incorporating an array of resonators. J Acoust Soc Am. 1979;65(S1):S52–6.

Kinsler LE, Frey AR, Coppens AB, Sanders JV. Fundamentals of acoustics. 4th ed. New York: Wiley; 2000.

Kim MS. Absorption characteristics of resonator array panel or low frequency applications. The 32nd International Congress and Exposition on Noise Control Engineering, Korea Advanced Institute of Science and Technology; 2003.

Koopmann GH, Neise W. The use of resonators to silence centrifugal blowers. J Sound Vib. 1982;82(1):17–27.

Neise W, Koopmann GH. Reduction of centrifugal fan noise by use of resonators. J Sound Vib. 1980;73(2):297–308.

Selamet A, Dicky NS, Novak JM. Theoretical, computational and experimental investigation of Helmholtz resonators with fixed volume: lumped versus distributed analysis. J Sound Vib. 1995;2(187):358–67.

Dickey NS, Selamet A. Helmholtz resonators: one-dimensional limit for small cavity length-to-diameter ratios. J Sound Vib. 1996;3(195):512–7.

Tang SK. On Helmholtz resonators with tapered necks. J Sound Vib. 2005;279(3–5):1085–96.

Mbailassem F, Gourdon E, Leclère Q, Redon E, Cambonie T. Sound absorption prediction of linear damped acoustic resonators using a lightweight hybrid model. Appl Acoust. 2019;150:14–26.

Zhao X-D, Yu Y-J, Wu Y-J. Improving low-frequency sound absorption of micro-perforated panel absorbers by using mechanical impedance plate combined with Helmholtz resonators. Appl Acoust. 2016;114:92–8.

Beck M, Geoghegan R. The art of proof: basic training for deeper mathematics. Springer Science & Business Media; 2010.

Bóna M. A walk through combinatorics. 3rd ed. New Jersey: World Scientific; 2011.

Vér IL, Beranek LL. Noise and vibration control engineering-principles and applications. 2nd ed. New Jersey: Wiley; 2006.

Morse PM, Ingard KU. Theoretical acoustics. New York: McGraw-Hill, Inc; 1968.

Falsafi I, Ohadi A. Improving absorption bandwidth of microperforated panel by stepping the cavity. In Proceeding of 22th International Conference on Sound and Vibration, ICSV22, 2015, Florence, Italy.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Basirjafari, S. Innovative solution to enhance the Helmholtz resonator sound absorber in low-frequency noise by nature inspiration. J Environ Health Sci Engineer 18, 873–882 (2020). https://doi.org/10.1007/s40201-020-00512-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40201-020-00512-w