Featured Products:

Product Description

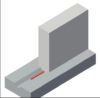

Install Earth Shield® Stainless Steel Waterstop in all concrete joints. Waterstop should be centered in, and run the extent of the joint. All changes of directions should be prefabricated, leaving only butt-welding for the field. Splices in stainless steel waterstops shall be welded using a TIG (recommended) or MIG process utilizing a welding rod to match the stainless (weld rod: 316ELC; diameter — .035 to .045). Repair damaged waterstops by removing damaged portions and patching. Patches shall overlap a minimum of 1 inch onto an undamaged portion of the waterstop. Weld all straight run material edge-to-edge (no overlapping). If installed in an expansion joint, assure backside (or open end of the center “V”) is covered completely with tape and the annulus (between tape and waterstop) is filled with 7/8” diameter backer rod before concrete pour. The tape and backer rod allows the center “V” to remain open allowing for joint movement. (Tape and backer rod is not necessary for non-moving contraction and construction joints.) More detailed installation instructions are in our Standard 3-part Specifications.

Manufacturer Info

JP Specialties

JP Specialties has been manufacturing the Earth Shield® line of waterstops for over 20 years. We are dedicated to providing technical support for a complete range of waterstops and focused on being the best. Our products (PVC, TPV, SS, and strip-applied waterstops) have the best physical properties in the industry, and more importantly, we provide unmatched service and technical support.

At the engineering level, our technical leaders are officers in multiple ACI committees. We were the first waterstop company to get NSF 61 approval, and our owner has written the leading professional resource book used in the construction industry (Little Book of Waterstop by David Poole). Our popular accredited seminar (worth one hour CE credit) is presented nationally and internationally to over 200 engineering and owner offices with many thousands of attendees.

We also provide contractors with aggressive pricing, extensive inventories, and factory fabrications for both standard and custom fittings. JP Specialties also does on-site welding schools and certifies attendees for the proper welding of waterstops.

Please check out our Waterstop CAD website as well!